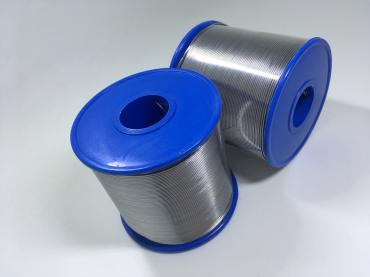

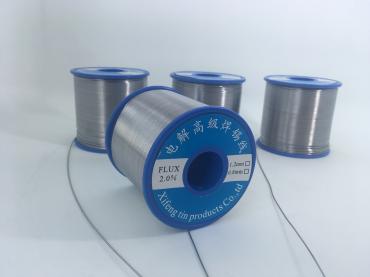

| Name: | 60/40 flux core solder |

| Name: | 60/40 flux core solder |

| Alloy: | Tin Lead |

| Composition: | 60/40 |

| Core: | Flux core |

| Origin: | China |

Product Description

60/40 flux core solder

General description of 60/40 flux core solder

60/40 flux core solder is a solder that made into solder wire that used for manual soldering or for automatic feed soldering. It's a tin and lead solder alloy, made of 60% tin (Sn60) and 40 of lead (Pb40), and implemented with a pre-flux core. Don't confuse this type 60/40 flux core solder with the 40/60 flux core solder, as the 40/60 is just the opposite composition that has 40% tin and 60% of lead (more lead than more tin), make sure you buy the right specification.

How many different types of 60/40 flux core solder

Depending on the nature of the flux core, we can divide the 60/40 flux core solder into below 3 types:

Rosin flux core 60/40 solder. The flux is based on rosin, a natural ingredient extract from pine tree, neutral flux type, generally is no cleaning is required.

Water soluable flux core 60/40 solder. This is made with more aggressive flux, but the flux can be washed just with water and it has to be cleaned after soldering because the flux is aggressive.

Acid flux core 60/40 solder. This is made with acid based flux, very aggressive one, also cleaning after soldering is a must.

What are the 60/40 flux core solder used for?

For the above 3 types of 60/40 flux core solder, their application fields as below:

Rosin flux core 60/40 solder is used for general soldering of electronics, for both industrial and repair works. A very handy solder that only leaves very little transparent, no corrosive residue.

Water soluable flux core 60/40 solder is also used for soldering of electronics with higher requirements, especially like applications of aerospace stuffs, high end equipment that intended and designed for a long service life, in such case water soluable flux core is a good option, after soldering make sure the solder area is well cleaned throughout.

Acid flux core 60/40 solder is more for soldering of metals, like copper, galvanized steel, nickle metal etc. Reason of acid flux core for this application, is such acid nature flux can clean the tarnished metal surface well and helps the solder to flow quickly to fill up the joints.

Contact us if you need to buy the 60/40 flux core solder, our Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/wechat: 008613450770997, main website: www.xfsolder.com