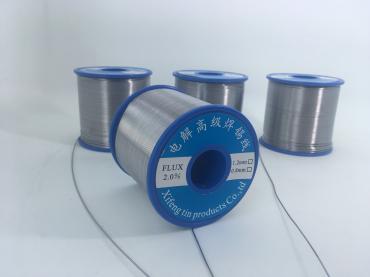

| Name: | Rosin activated core wire asahi solder |

| Name: | Rosin activated core wire asahi solder |

| Alloy: | Tin Lead or Lead free |

| Form: | Solder wire |

| Core: | Rosin Flux 2.0 |

| Place of origin: | China |

Product Description

Rosin activated core wire asahi solder

What is Rosin activated core wire asahi solder?

The Rosin activated solder wire is with a fully activated rosin flux. It's a general-purpose solder wire for use in applications where mildly activated fluxes are too weak. RA cored solder wire is strong enough for excellent tarnish and oxide removal, and will produce bright shiny solder joints. RA wire will leave slight to moderate post process residues that may be left on noncritical applications, but should be removed from any critical applications. RA cored wire meets Mil-Spec cleanliness requirements post-cleaning. IPC flux classification for this material is ROM1.

What alloy Rosin activated core wire asahi solder is available in?

1. Tin lead solder wire with rosin activated core: Sn63Pb37 solder wire, Sn60Pb40 solder wire, Sn40Pb60 solder wire

2. Lead free solder wire with rosin activated core: SAC305 solder wire, SAC0307 solder wire, SAC07 solder wire

Application of Rosin activated core wire asahi solder:

1. Solder iron tip temperature should be between 340°C-400°C (650°F-750°F) for Sn63, Sn62 and Sn60 alloys, 370°C-425°C (700°F-800°F) for Sn/Ag and Sn/Ag/Cu alloys

2. Hold the solder iron at a 45° to 60° angle to the work surface.

3. The solder iron should contact both the component lead and PCB pad surface.

4. Solder and flux should flow onto both the lead and pad or lead and barrel to promote optimum flux activity to the joint being worked.

If you need to buy the Rosin activated core wire asahi solder, contact us, Whatsapp / Wechat: 008613450770997 ; Email: xfsolder@gmail.com or xfsolder@163.com, main website: www.xfsolder.com